How to Maintain a Cardboard Baler Machine: Baler Safety Checklist

Waste recycling is not only good for the environment, it also reduces the commercial waste disposal costs of a business. Effective cardboard and plastic recycling, for example, can lower the frequency of required waste collections as well as keep your premises tidier and reduce clearance time.

In some cases, using cardboard balers and/or plastic balers to achieve effective waste management can even generate income on the sale of recycled raw materials.

It doesn’t take long for a business to appreciate the benefits of recycling balers, making them an essential part of daily business operations. At the same time, commercial waste compactors and balers are powerful pieces of equipment, capable of pressing forces up to 60 tonnes, so it’s vital that waste balers are maintained both for the safety of employees as well as the efficiency of your business.

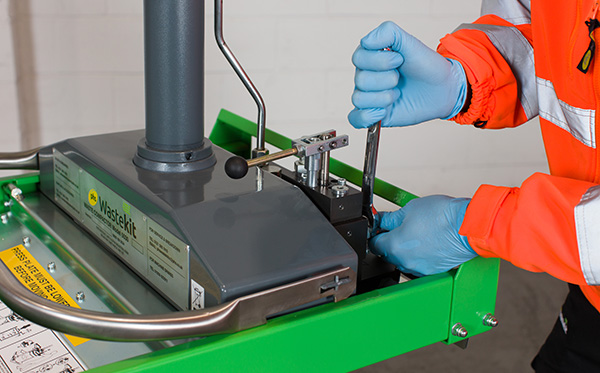

phs Wastekit offers a range of compactors and balers to help you streamline your waste management process and while we include periodical maintenance for all of our rented commercial waste balers and can provide service plans for your own equipment, it’s important to take time to regularly maintain plastic balers or cardboard balers.

Following a simple maintenance routine will mean minimal downtime and maximum benefit from your waste balers. Here’s our list of top tips for smooth running to add to your plastic and cardboard baler safety checklist:

1) Training is paramount with recycling balers

Baler safety training and operator instructions come as standard with each horizontal baler and vertical baler from phs Wastekit. Safety is your responsibility as an employer, so you must ensure that only properly trained and responsible staff are allowed to use the baler, and that they always follow the cardboard baler safety instructions. This will keep your staff safe and help keep the cardboard balers/plastic balers running smoothly.

2) Keep the strays away from your waste recycling

Only use recycling balers for paper, cardboard or soft plastic waste and make sure that rogue items such as glass, metal and wood do not contaminate your waste collection. There are special compactors for these, such as phs Wastekit’s glass bottle crusher. Mixed raw materials will result in your cardboard recycling or plastic recycling bales being rejected from recycling facilities. Hard or sharp materials can damage the compactor and baler mechanism of vertical balers or horizontal balers, resulting in extensive repair. Liquids can render a whole batch of waste recycling materials unusable, and aerosols or gas containers can explode if crushed or punctured – another no-no for baler safety.

3) A little cardboard baler cleaning goes a long way

Lightly cleaning the inside and outside of waste collection equipment is an easy way to keep it working well. A quick brush to remove leftover cardboard and dust or plastic remnants from the inside of the recycling baler can help avoid blockages, and a wipe down to remove any accidental liquid spillage or moisture build up can prevent rust. Always observe cardboard baler safety instructions and make sure that the waste baler is turned off before you start to clean.

4) Keep your compactors and balers topped up

Don’t get caught short with a lack of tools and accessories for your compactors and balers. Running out of compactor sacks, baling twine, wire or strapping can put a halt to recycling bale production and your premises will soon get clogged up with plastic and cardboard waste. Keep a stock close at hand and regularly check that waste balers are loaded.

5) Don’t be afraid to call in the compactor and baler experts

Professional and regular attention by specialised providers will keep your waste management equipment running safely and effectively. phs Wastekit offers year-round maintenance and service plans for their rented compactors, horizontal balers and vertical balers of various capacities, which we are also happy to apply to your own waste recycling equipment.

Poorly functioning plastic or cardboard balers can result in business downtime and, more worryingly, can put your staff at risk. Adding these simple steps to your baler safety checklist can protect your staff and your business between regular planned servicing. Speak to phs Wastekit today to discover how waste management equipment can make a difference to your business.