The benefits of large compacting and baling machines – which is right for your business?

In our fast-paced and efficiency-driven world, businesses are constantly seeking ways to reduce costs, streamline operations and promote sustainability. For businesses that generate a substantial volume of waste, large sized baling and compacting machines can have a real impact.

Phs Wastekit look at the benefits of larger machines and what type of machine could make a difference for your business.

Benefits of large baling and compacting machines

Minimise the volume of waste

- This translates into fewer waste collections, reducing costs and ensuring greater efficiencies.

Labour savings

- Large machines with automated or semi-automated loading systems can deliver significant labour savings.

Rebate opportunities

- Larger baling machines offer opportunities to increase the amount of recyclable waste that a business could receive rebates for.

Environmental benefits

- Fewer waste collections mean less trucks on the road, reducing emissions. A compacting machine will help you reach your sustainability goals and improve ESG.

Improved health and safety

- Overflowing bins or stacks of waste are unhygienic and pose safety hazards, including trip hazards and vermin. These machines help to keep work environments neat, tidy and free from unsightly clutter and smells.

High ROI

- While the upfront investment of a large machine can seem costly, the long-term return on investment is substantial. Savings on waste management, improved efficiency, reduced labour costs, and potential recycling rebates all contribute to a quick and measurable ROI. Many businesses find that large machines pay for themselves within just a few years.

Static Compactors

Static compactors stay on-site at all times with the machine attaching to a container for emptying. They are a very reliable piece of equipment that ensures there is no downtime when they are full. They are ideal for high throughputs and large items. They are generally used for general waste but can also compact cardboard, plastics and wet items amongst others.

They can be handloaded or tippers can be mounted on either side or the rear of the machine. The most common tippers, or bin lifters, for these machines include trunnion, comb and universal styles, as well as bulk feeders, dolavs and pallet lifters.

We also offer bespoke options to meet our customers’ exact requirements, as well as conveyors for loading large quantities at a high rate, including auto start and multiple branch options, and oversized hoppers for loading with digger buckets.

Static compactors can be suitable for factories and warehouses, distribution centres, logistics companies and large manufacturers, as examples.

Portable Compactors

Portable compactors offer flexibility and the ability to relocate if needed. The machine itself is removed from site, emptied and returned. Skip lift portable machines are ideal when space is restricted as they are collected via a skip lift truck, so they require less space for collection. They can be hand-loaded or have bin lifts or tippers added, depending on the customer’s needs.

These are generally used for general waste, but they can handle other materials too including cardboard and plastics. They can also be adapted for wet waste.

Portable compactors can be suitable for schools, shopping centres, hospitals, food manufacturers, service stations and office blocks – anywhere where space is restricted.

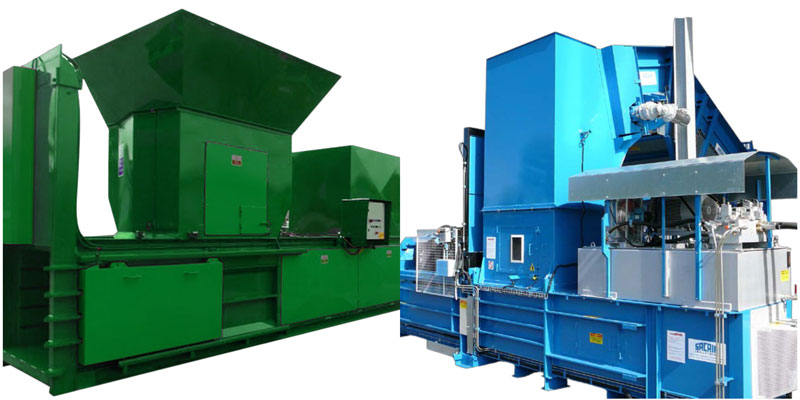

Semi-Automatic Balers

Semi-automatic balers are ideal for high throughput of up to two tons an hour. They are suitable for both cardboard and plastic and have an automatic start and bale ejection system. Bales of cardboard and plastic can be upwards of 400kg depending on the chosen specification.

These machines can be fed by hand, via a conveyor or via bin lifts including trunnion, comb and universal styles. They can also be adapted with an oversized hopper for digger bucket loads.

Semi-automatic balers can be suitable for large garden centres, retailers, manufacturers or packaging facilities, for example.

Fully Automatic Balers

Fully automatic balers are used for very high throughputs of cardboard or plastic. They have automatic start, tying and bale ejection systems and, again, bale weights are upwards of 400kg depending on the machine specification chosen. They can also be fed by hand, a conveyor or via a variety of bin lift options.

Fully automatic balers can be suitable for large retail chains, e-commerce fulfilment centres, large distribution centres, manufacturers and warehouses, for example.

EPS (polystyrene) compactors

Polystyrene compactors turn waste EPS into blocks for recycling and come in a variety of sizes for every business need and can offer high rebate returns on the material.

Want to know more?

Talk to our experienced and professional team to find out

the right machine for your exact needs and start your sustainability journey

today.

Contact

phs

Wastekit on 0800 169 3534

Email us:

wastekitsales@phs.co.uk

phs

Wastekit

one of the UK’s leading suppliers of

balers, compactors and bins, providing businesses with a whole service approach

that supports them on their sustainability journey.

The team offers servicing and maintenance packages right across

the UK, as well as partnerships with recycling companies to support customers

on the road to greener waste management and greater sustainability goals.